Weidouli's Globe type control valves are combined characteristics of CV3000 flow path design with our own advantages. The development of structural design ideas, innovative design, optimization and improvement of the valve structure, suitable for a variety of harsh working conditions.

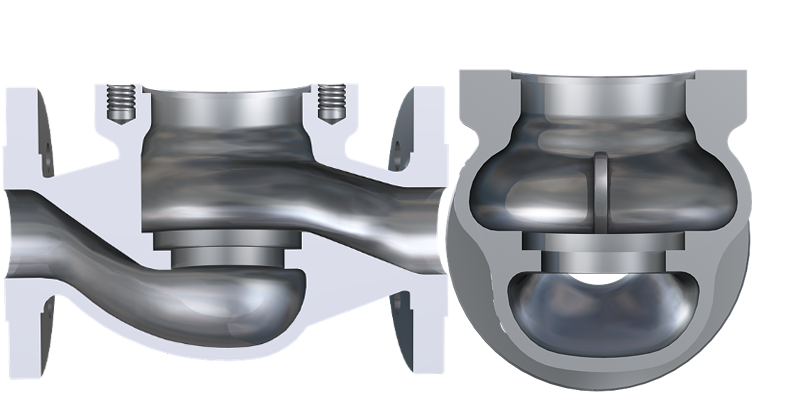

1. The interior of the valve adopts an S-shaped flow path, the entire valve body flow path is closer to the flow line than the traditional ball design, reducing the body resistance coefficient and increasing the flow capacity of the valve body.

2. The distributor in the valve effectively eliminates the rotating swirl caused by the medium flow and improves the flow capacity and the stability of the valve.

1. Excellent design and advanced processing technology ensure the IEC required control accuracy.

2. Modular structure can choose the best material and processing technology according to different functional requirements, can improve the service life of products and convenient valve maintenance and valve trim replacement.

3. Self-centering structure: The valve can be sealed strictly when it is closed, without precise grinding.

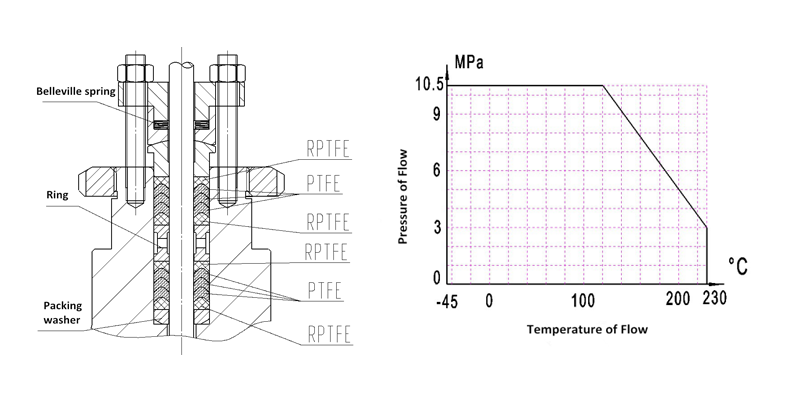

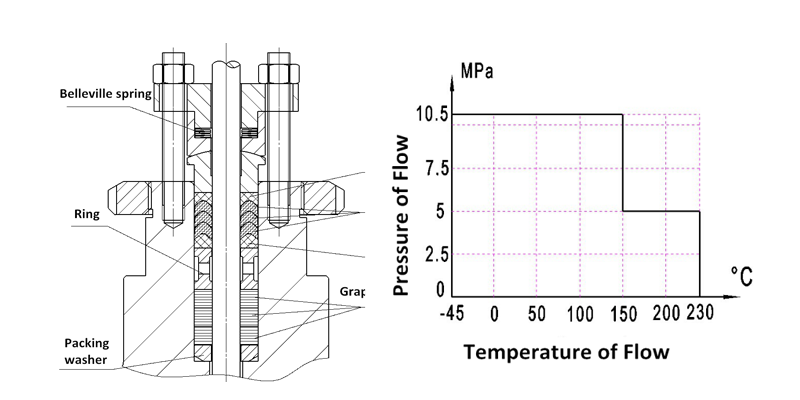

Advanced combined stuffing seal

Any structure and any material has its good and bad points. They can complement each other and achieve the best sealing effect by ingenious combination design and reasonable collocation.

V type PTFE packing structure

Low friction without lubrication

Suitable for a variety of media

Packing ring is loaded by a belleville spring and automatically adjusted

Working temperature:-40℃-230℃

Need stem with high finish

Not suitable for nuclear radiation (packing is easily damaged)

Graphite packing structure

High working temperature

Temperature reach 649℃

The packing ring is loaded by a Belleville spring and automatically adjusted

Suitable for a variety of media and nuclear radiation applications

Long service life

Need to lubricate when in high working temperature

High friction, easy to produce hysteresis

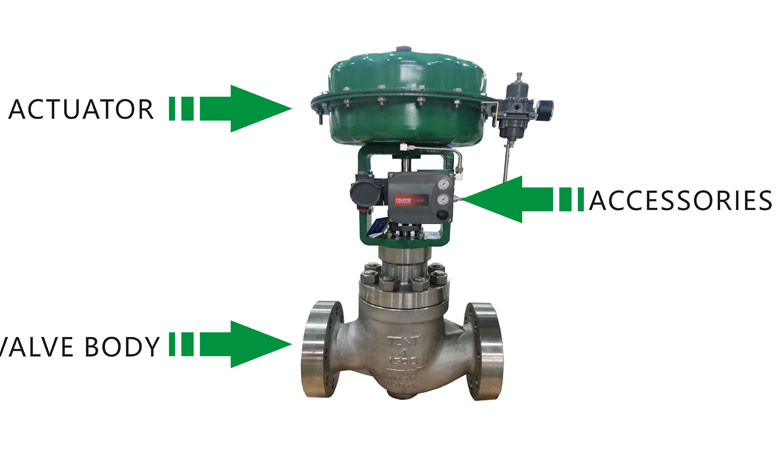

Actuator

AM pneumatic film actuator can provide greater output force than traditional actuator since it adopts innovative high-strength rolling diaphragm design, and the air supply pressure can reach 0.6MPa. At the same time, the precision of the actuator is greatly improved with the constant effective area of the diaphragm and the high precision spring.

AA additional devices, to improve the performance, increase function, and expand the application of the control valve, such as positioner, handwheel mechanism, booster, etc.

Accessories

Additional devices, to improve the performance, increase function, and expand the application of the control valve, such as positioner, handwheel mechanism, booster, etc.