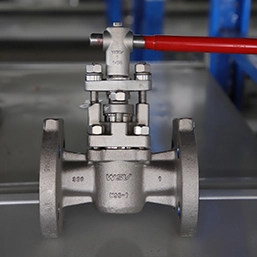

Weidouli titanium plug valves are designed and manufactured for the process industries to handle liquids that contains slurry and sludge or liquids which are hazardous, corrosive ect. harsh working conditions with the advantage of deposit-free, anti-crystallization, anti-corrosion, and anti-high temperature and pressure.

The most distinct property of Titanium is its outstanding resistance to corrosion, especially highly resistant to acids, aqua regia and moist chlorine in water. Weidouli plug valves are meticulously machined in our own precision CNC machining centers where it must pass extensive quality control procedures and undergo an extensive heat treatment and stress relieving process to ensure molecular integrity and prolong the valve's usage life.

Design standard: API, ASME, EN, ISO, JIS, DIN, BS, GB

Pressure rating: CLASS 150LB~600LB, 1.0MPa~11.0MPa, JIS 10K~40K

Size range: NPS1/2” ~24”, DN15~DN600

Bore: Full bore, Reduced bore

Standard connections: flange, threaded, butt weld, socket weld

Sleeve Material: PTFE, RPTFE, TFM, GF2P, PPL, PFA

Seawater Desalination: Titanium valves are almost non-corrosive in seawater, making long-term immersion possible.

Pulp and Paper: The pulp in the bleaching section contains a small amount of chloride ion, and the titanium valve bears excellent resistance to chloride-ion corrosion.

Smelting: Titanium valves boast the advantages of safety, reliability and long service life.

Aviation and Military: Titanium valves are of lightweight, high mechanical strength and virtually non-magnetic.

Packaging- Titanium valves are packed in superior plywood boxes. Every valve is secured by a plastic cap to avoid any damage in transportation. This accumulated product is also packed in polythene lock bags to avoid any pollution.