Titanium alloy refers to a variety of alloy metals made of titanium with other metals. Titanium is an important structural metal developed in the 1950s. Titanium alloy has high strength, good corrosion resistance, and high heat resistance.

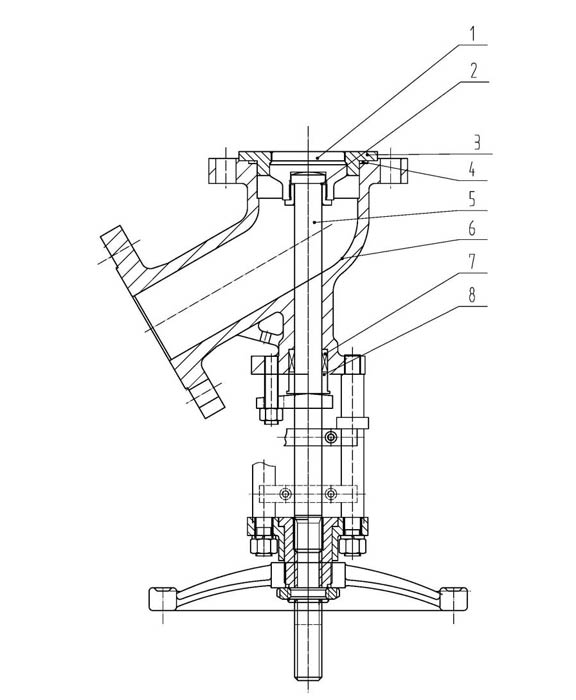

Upward design discharge valves

The upward type discharge valve is the upward movement of the valve disc (plunger). When the valve is opened, the direction of movement is the same as the medium force, so the opening moment is smaller than the closing moment. When the upper spread valve is fully open, the spool is extended to the tank; the upswing moves inside the valve body just like a normal globe valve. The working principle of the up-spread discharge valve is the up-down valve disc, which eliminates the residual phenomenon of the medium at the bottom of the container. It is mainly installed in the reaction pot with slurry type, turbine type, or propulsion type agitator. When the valve is opened, the valve core can not reach into the reaction pot, so that the material can be discharged dynamically. The discharging effect is good and there is no material accumulation at the bottom of the pot.

Downward design discharge valves

The downward type discharge valve is used for the reaction kettle discharge of the frame-type anchor agitator. When it is fully open, the spool is extended to the tank. The lower development type discharge valve for the valve disc (plunger) downward movement valve open, open the direction of movement and the medium force is the same, so the opening moment is smaller than the closing moment.

Downward discharge valves

Design Features

Desgin :HG5-89-1 &HG-16-79

Flanged Ends: ASME B16.5 RF

Test:ASME 598

Parts & Material

No. | Part Name | Material |

1 | Disc | Titanium |

2 | Disc bonnet | Titanium |

3 | Seat | Titanium |

4 | Gasket | Titanium+Graphite |

5 | Stem | Titanium |

6 | Body | Titanium |

7 | Packing | Graphite |

8 | Gland bushing | Titanium |