Common super austenitic stainless steels used in the valve industry are UNS S31254 (254SMO and AL6XN). They are predominantly used to obtain both higher strength and improved resistance to crevice corrosion chloride pitting compared to 316 SS. This improved corrosion resistance comes from the higher Ni and Mo content, and nitrogen strengthens the material. Desalination, food processing, chemical processing, and even seawater services use super austenitic stainless steels as an economical selection in cases where high strength and good corrosion resistance are needed.

Name | Castings grades | Forgings grades | Bars grades |

904L | 904L | A182 F904L | B649 N08904 |

254SMO | A351 CK3MCuN | A182 F44 | A276 S31254 |

AL-6XN | A351 CN3MN | B462 N08367 | B688 N08367 |

ALLOY 20 | A351 CN7M | B462 N08020 | B473 N08020 |

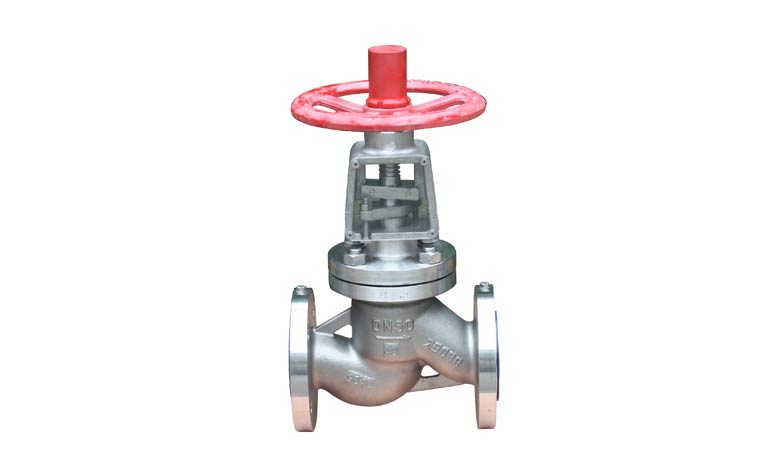

Another popular super austenitic stainless steel is UNS N08904 (904L), which has a 5% Mo content. It is used for a variety of valve components for inorganic acid environments, typically used in Fertilizer plants with sulfuric and phosphoric conditions. It is also found in the pulp and paper manufacturing, pharmaceutical, and power industries. The material is used mainly for trim components, but new specialized grades with higher strength are also being used for valve pressure--containing components. Sometimes, 904L globe valves can be used for oxygen service.