Stainless Steel is the short name for Stainless acid-resistant Steel. The steel which resistant to air, steam, water, and other weak corrosion medium or Stainless Steel is called Stainless Steel; and which resistant to chemical corrosion medium (acid, alkali, salt, and other chemical etching) corrosion of steel is called acid-resistant steel.

According to their different texture, Stainless steel is often divided into Martensite steel, ferrite steel, austenitic steel, austenitic - ferrite (dual-phase) stainless steel, and precipitation hardening stainless steel.

Weidouli mainly supply Austenitic steel valves

Austenitic stainless steel refers to stainless steel with an austenitic structure at room temperature. When Cr is about 18%, Ni is about 8%~25%, C is about 0.1%, the steel has a stable austenite structure. Austenitic Cr-Ni stainless steels include famous 18Cr-8Ni steels and high Cr-Ni series steels developed by adding Cr and Ni content and Mo, Cu, Si, Nb, Ti, and other elements on this basis. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but the strength is low, it is impossible to strengthen through phase transformation, can only be strengthened through cold working, such as the addition of S, Ca, Se, Te, and other elements, it has good ability of machining

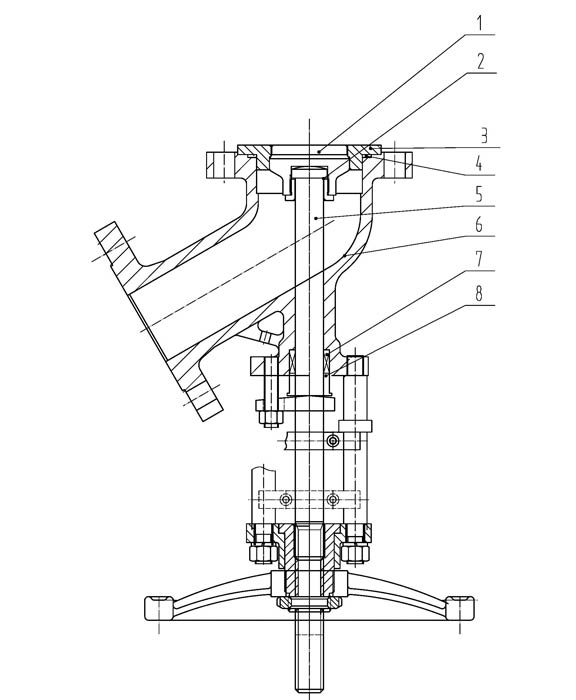

Downward discharge valves

Design Features

Design :HG5-89-1 &HG-16-79

Flanged Ends: ASME B16.5 RF

Test: ASME 598

Parts & Material

No. | Part Name | Material |

1 | Disc | Stainless |

2 | Disc bonnet | Stainless |

3 | Seat | Stainless |

4 | Gasket | Stainless+Graphite |

5 | Stem | Stainless |

6 | Body | Stainless |

7 | Packing | Graphite |

8 | Gland bushing | Stainless |

Weidouli also can offer upward discharge valves.