Duplex stainless steel is a steel which has half of ferrite phase and half of austenitic phase in its quenching structure,and generally the minimum phase content must be up to 30%.

Duplex stainless steels containing molybdenum have good performance of resistance to chloride stress corrosion under low stress.

Duplex stainless steels containing molybdenum have good corrosion resistance.

It has good resistance to corrosion fatigue and wears and corrosion.

Good comprehensive mechanical properties.

Good weld-ability, the low tendency of hot cracking. Generally, it doesn't need preheating before welding and doesn't need heat treatment after welding. It can do dissimilar welding with 18-8 type austenitic stainless steel or carbon steel.

Compared with austenitic stainless steel, it has higher thermal conductivity and a low linear expansion coefficient. It is suitable for the lining of equipment and the production of composite plates

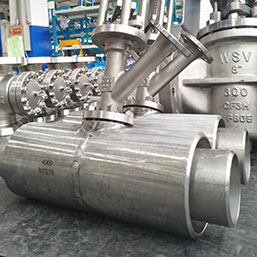

Downward discharge valves

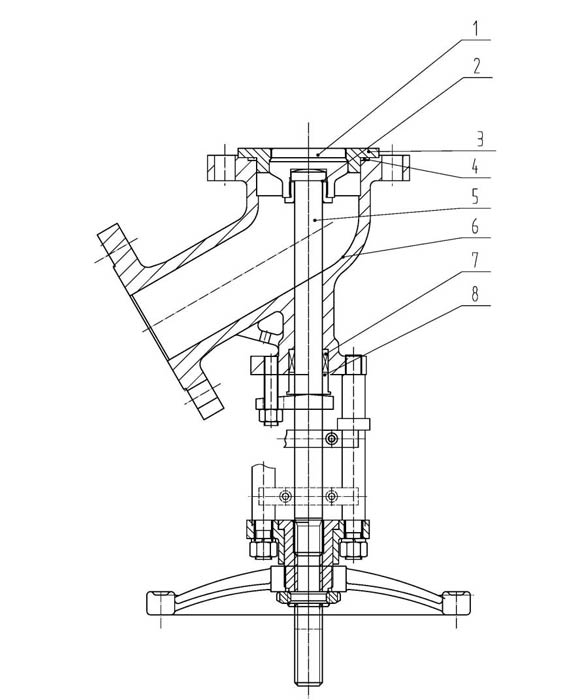

Design Features

Desgin :HG5-89-1 &HG-16-79

Flanged Ends: ASME B16.5 RF

Test:ASME 598

Parts & Material

No. | Part Name | Material |

1 | Disc | Duplex |

2 | Disc bonnet | Duplex |

3 | Seat | Duplex |

4 | Gasket | Duplex+Graphite |

5 | Stem | Duplex |

6 | Body | Duplex |

7 | Packing | Graphite |

8 | Gland bushing | Duplex |

Weidouli also can offer upward discharge valves.