Hastelloy is a nickel-molybdenum alloy. It contains ultra-low carbon and high Ni, Mo, and Cr elements, which belong to corrosion-resistant and high temperature-resistant materials.

There are many different grades of Hastelloy, many of which are nickel-chromium-molybdenum alloys. Each of these grades has been optimized for a specific purpose, but all of them are highly resistant to corrosion.

The Corrosion-Resistant HASTELLOY alloys are widely used by the chemical processing industries. The need for reliable performance leads to their acceptance and growth in the areas of energy, health, and environmental, oil and gas, pharmaceutical, and flue gas desulfurization industries.

Excellent corrosion resistance in the strong corrosion oxidative and the reducible acid medium.

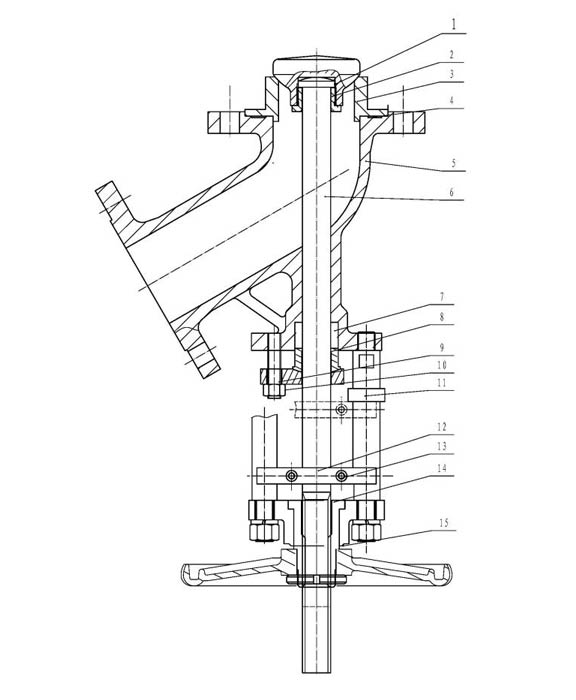

Upward discharge valves design Features

The gasket is placed in the concave groove of the valve body, the gasket can keep the elasticity for a long time and the sealing is reliable.

Integral forging valve core design, with better strength.

Enlarge the size of the stem and connection rod made the valves more stable and firm.

Waist drum structure valve bodies have good streamline, it can increase flow capacity and reduce medium deposition.

Spring-loaded packing design provides more reliable sealing and realize packing seal online adjustment

Valve core have a guide device to protect the stem from deviation

Parts & Material

No. | Part Name | Material |

1 | Disc | Hastelloy |

2 | Disc bonnet | Hastelloy |

3 | Seat | Hastelloy |

4 | Gasket | Hastelloy+Graphite |

5 | Body | Hastelloy |

6 | Stem | Hastelloy |

7 | Packing | Graphite |

8 | Gland bushing | Hastelloy |

9 | Stud | 304 |

10 | Hex nut | 304 |

11 | Prop | 304 |

12 | Guide plate | 304 |

13 | Screw | 304 |

14 | Stem nut | DAL9-4 |

15 | Support seat | 304 |

Weidouli also can supply downward discharge valves